Elevate Your Product Design with Extrusion of Plastics Know-how

Wiki Article

Plastic Extrusions: Enhancing Performance and Performance With Plastic Extrusions

Are you wanting to boost performance as well as performance in your sector? Look no more than plastic extrusions. With their countless advantages as well as essential factors influencing efficiency, plastic extrusions are the service you need.In this article, we will check out methods for enhancing efficiency and advancements that can take your operations to the next degree. Get ready to uncover real-life case researches showcasing the effective implementation of plastic extrusions.

Don't lose out on this chance to change your business.

Benefits of Plastic Extrusions in Enhancing Effectiveness

You can substantially boost your performance with plastic extrusions. These functional elements provide numerous advantages that can enhance effectiveness in numerous sectors.To start with, plastic extrusions are light-weight, making them simple to take care of and set up. Whether you remain in the construction, auto, or product packaging sector, this attribute enables problem-free and fast setting up, conserving you beneficial effort and time.

In addition, plastic extrusions are extremely customizable, allowing you to tailor them to your specific needs. With the capacity to create intricate sizes and shapes, you can optimize your processes and maximize productivity.

Plastic extrusions are recognized for their resilience and also resistance to tear and also wear. This implies that once mounted, they call for marginal upkeep, decreasing downtime and also enhancing your total functional efficiency.

Furthermore, plastic extrusions offer excellent thermal as well as electrical insulation residential or commercial properties, making them suitable for a vast array of applications. From cable management to weatherproofing, these components can help simplify your procedures as well as improve performance.

Key Factors Affecting Performance in Plastic Extrusions

One of the crucial elements that affect efficiency in plastic extrusions is the correct choice of products. When it pertains to plastic extrusions, picking the right materials is vital for accomplishing optimum efficiency as well as effectiveness. The type of material utilized can substantially affect the extrusion procedure, in addition to the quality and resilience of the last item.By selecting products that have the appropriate residential or commercial properties as well as features, you can make sure that the extrusion process runs efficiently as well as effectively. Making use of materials with good heat resistance can protect against melting or deformation during the extrusion procedure. Materials with high stamina and resilience can result in a last item that is strong as well as durable.

Another crucial variable to consider is the compatibility of the materials with the extrusion devices. Various materials may call for various processing specifications, such as temperature level and also speed, to accomplish ideal outcomes. Picking products that are well-suited to the particular extrusion devices being utilized can assist protect against concerns such as blocking, uneven flow, or poor item high quality.

In addition to product option, various other elements such as die style, processing conditions, and operator know-how likewise play a duty in the performance of plastic extrusions. By beginning with the correct choice of products, you can establish a strong foundation for achieving efficient and premium extrusions.

Approaches for Maximizing Performance in Plastic Extrusions

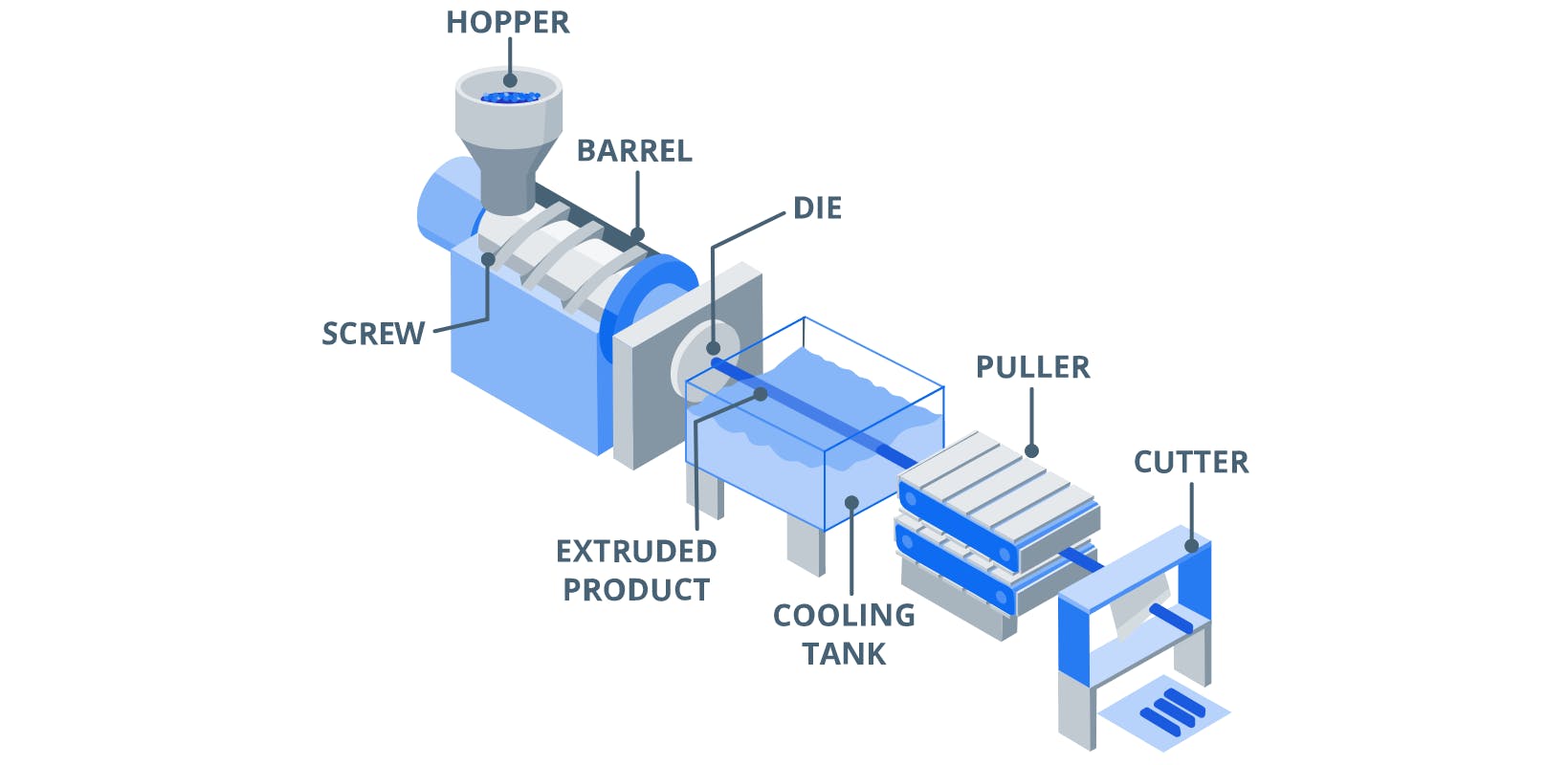

To optimize performance in plastic extrusions, it is essential to thoroughly consider elements such as die layout, processing conditions, and operator knowledge. By focusing on these crucial areas, you can considerably enhance the efficiency and also efficiency of your extrusion process.The layout of the die plays a vital duty in establishing the quality and uniformity of the extruded plastic. Furthermore, thinking about factors such as land length, land clearance, as well as leave angle can help in reducing waste as well as improving the overall effectiveness of the extrusion process.

Next, allow's discuss handling problems. Temperature level, pressure, and also speed are critical aspects that affect the extrusion process. Effectively regulating these aspects can assist in accomplishing uniform thaw flow and preventing problems like thaw fracture or item problems. It's important to keep track of and also readjust these problems to maximize the performance as well as performance of the extrusion procedure.

Finally, driver experience plays a substantial function in making the most of efficiency. Trained drivers can recognize and also repair issues rapidly, making certain smooth operation and very little downtime. Supplying proper training as well as ongoing assistance to your drivers can improve their skills and also expertise, bring about boosted performance as well as productivity.

Advancements in Plastic Extrusions for Enhanced Performance

When it concerns enhancing the performance article source of your plastic extrusion procedure, remaining upgraded on the current technologies is key. Technology is frequently developing, and also brand-new advancements in plastic extrusions can aid improve the effectiveness and also efficiency of your procedures.One of the most recent advancements in plastic extrusions is making use of advanced air conditioning systems. These systems ensure that the extruded plastic is quickly cooled down as well as strengthened, causing greater manufacturing speeds as well as boosted product quality. By including these cooling down systems right into your procedure, you can lower cycle times as well as raise efficiency.

By fine-tuning these criteria, you can enhance the extrusion process and also attain precise and regular outcomes. This not just enhances item top quality however also lowers waste and also minimizes downtime.

Innovations in product solutions have led to the development of brand-new high-performance plastics. These plastics supply improved stamina, resilience, and also heat resistance, making them ideal for a vast variety of applications - extrusion of plastics. By using these cutting-edge materials, you can improve the performance and capability of your items

Study: Effective Implementation of Plastic Extrusions for Effectiveness and also Performance

Looking at successful study can supply useful understandings on how executing plastic extrusions has actually improved efficiency as well as efficiency in numerous sectors.One such situation research study originates from the auto industry. Using plastic extrusions in the production process has actually substantially reduced production time and enhanced general efficiency. By replacing conventional steel components with plastic extrusions, suppliers structured their procedures and also attained expense financial savings.

Plastic extrusions have actually been utilized to enhance the efficiency of doors and also home windows. By using plastic extrusions rather of conventional materials like timber or metal, producers produced products that are extra resilient, weather-resistant, as well as energy-efficient.

In the packaging sector, plastic extrusions have actually changed just how items are packaged as well as shielded throughout transportation. Custom-designed plastic extrusions have actually enabled suppliers to create lightweight product packaging options that offer premium security against damage. This has decreased the danger of product damages during transportation and also decreased shipping prices for firms.

Conclusion

There you have it âEUR" plastic extrusions are a game-changer when it comes to improving performance as well as performance.site web By optimizing essential aspects and also executing ingenious methods, organizations can substantially boost their procedures. Whether it's minimizing waste, raising performance, or accomplishing price savings, plastic extrusions supply a service.

Don't just take our word for it, there are various effective situation research studies that show the effectiveness of plastic extrusions.

Why wait? Beginning checking out the benefits of plastic extrusions today and take your performance and efficiency to new heights. extrusion of click over here plastics.

With their various advantages and also vital factors influencing performance, plastic extrusions are the remedy you need.

One of the essential elements that influence efficiency in plastic extrusions is the correct option of products. When it comes to plastic extrusions, selecting the appropriate products is important for achieving optimum efficiency and performance. The use of plastic extrusions in the manufacturing process has dramatically minimized production time and also enhanced total effectiveness. Plastic extrusions have actually been used to improve the performance of home windows and also doors.

Report this wiki page